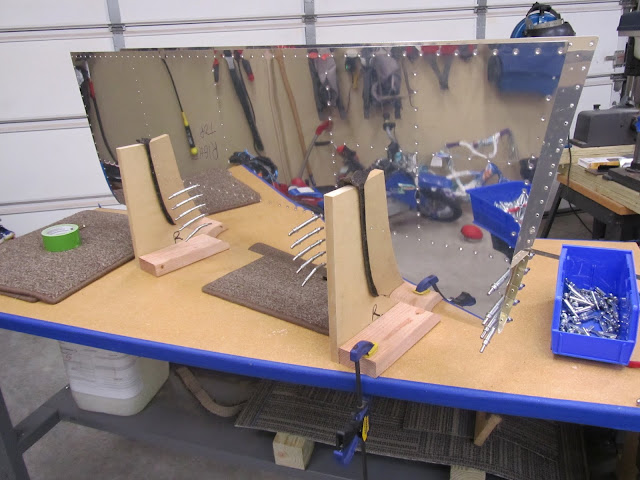

Once the rear spar was primed, it got cleco'd into position.

I'm not going to assume the readers of this blog know the intricate details of aircraft sheetmetal work, so I will try to explain the next problem I had to solve. Remember, the holes on the spar are all countersunk, and the skins are dimpled. What that means is that when you drill a #40 hole, you are drilling a hole that is .0985". That is the typical size hole that is drilled for a 3/32" rivet (which is only .09375")

Nearly every sheetmetal hole on a Van's aircraft is dimpled, and this in turn slightly expands that #40 (.0985") hole to some degree. The net affect is that the average "Cleco-Loc USA" cleco's, do not hold. They will hold in place, but once you buck a rivet nearby, they shoot out of the piece by themselves. I got tired of chasing cleco's around my shop and decided to solve the issue.

I called the folks at CLEVELAND AIRCRAFT TOOL and as always, they were a wealth of knowledge. I explained the problem, and they indicated their brand of cleco's (called Wedge-Loc) would indeed hold on a #40 dimpled hole. I think I ordered 125 of them (5 bags), and tried them out. They worked as advertised! Seriously, they are rock solid, so I ordered 5 additional bags, for a total of 250 of the wedge-loc cleco's. To keep them separate from the other type clecos, I had my son lay out some butcher paper and spray paint all of them red. The paint absolutely does not effect the operation at all...

LINK: Cleco's that work with dimpled holes

My son was there to help when the cleco's would fly, but I was determined to find a solution!

IKEA cart for holding my rivet stuff... Very handy...

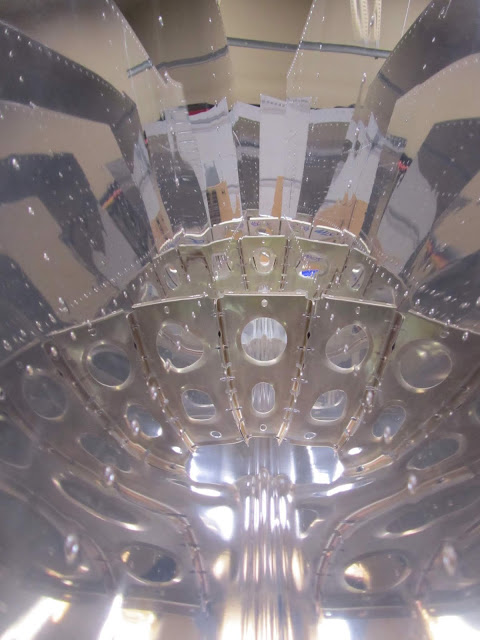

Also, I like to use green "Frog Tape" when working around the lightening holes on the HS. I didnt want to have my super heavy tungsten bucking bar fall into a hole, and make a dent. The tape also helps prevent scratches in the alclad.

This guy is the best assistant in the world.

The rivets holding the inspar ribs to the spar were extremely stressful. Just make sure you have a 12" long AN470 rivet set, and a huge angled bucking bar. Don't slip, because you are driving directly into the spar truss.... (sweating bullets...)

Eventually I finished. I touched up the paint and moved on.

TAHH DAHHH!!!! The horizontal stab is finished. I was very pleased with how it turned out. It's very satisfying to see something that looks like an airplane part...

I built a wall mount to free up the space in the garage. Nothing fancy, just enough to hold it secure, up and out of the way.

Just a couple of gate handles, velcro straps, and some huge zip-ties, just in case.

I learned a lot while completing the HS. Most of all, I learned to take my time, and don't rush. Everyone always says this, but it's so easy to fall into the "I think I know what the plans say here..." instead of going over and rereading the plans again.

Additionally, I feel that I learned a great deal about having the correct tool for the job. No matter what you do, if you have the wrong tool, you are going to screw something up. If you want to go cheap, you are going to get cheap results. Get the right tool, and you will thank yourself for it.

On to the elevators!